Anyone with a bored puppy will tell you, they can be a handful of trouble. Meet Olive, SSD member Jen F’s puppy.

Olive was getting bored in the middle of the day while Jen and her family were out of the home. Olive took to finding ways to entertain herself that was becoming a problem. Miscellaneous household items ended up in the back yard. To keep Olive busy during the day, Jen started hiding treat toys around the house. One of Olive’s favorite is an interactive toy that dispenses food as long as it gets flipped and rolled around.

Check it out here: http://store.petsafe.net/busy-buddy-kibble-nibble This Busy Buddy engages dogs to work for their food, which appeals to their natural hunting instincts. Jen soon discovered that there were a limited number of hiding spots in her house. Olive would find the toys almost immediately after she hid them, defeating the purpose of working up a good boredom.

Check it out here: http://store.petsafe.net/busy-buddy-kibble-nibble This Busy Buddy engages dogs to work for their food, which appeals to their natural hunting instincts. Jen soon discovered that there were a limited number of hiding spots in her house. Olive would find the toys almost immediately after she hid them, defeating the purpose of working up a good boredom.

Being a mechanical engineer, Jen started thinking up ways to delay the release of the ball so that it would provide satisfaction for Olive in the middle of the work day. The solution needed to be simple. Gravity based; so that the release mechanism would only require a single solenoid. Outlet powered; so that batteries wouldn’t be a continual cost. Random timer; so that Olive wouldn’t get used to what time it was released. Quick and easy loading instructions; so that anyone could load and start without a 50 page manual.

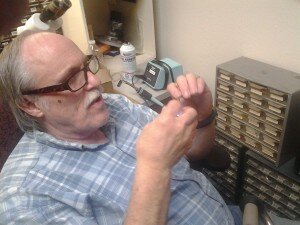

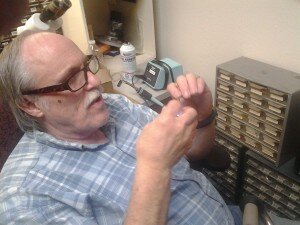

The prototype was put together with scrap lumber and eyeballing the gravity ramp. After an evening of mock-ups, Jen had a solid mechanical housing. Jen didn’t have much experience with electronics, however, she knew the hackerspace was a good resource for gurus. She met with John W., who had started working in a T.V. repair shop at the age of 10 in the 1960’s. He drew up a wiring diagram and pointed her in the direction of what she needed to get.

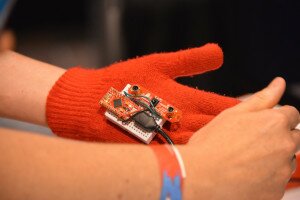

After a week, the only thing she couldn’t find was the timer. At a Solid State Depot Open House, she introduced her project to the group and asked for help. Another SSD member, Mike S., had just received an LCD/Button combo Arduino shield and wanting to put it to work, this seemed like a good project. After a few hours of programming, he had a random countdown timer mounted on a Spark Fun Red Board.

One of the issues that the gurus at Solid State Depot helped her solve was the amount of power that was getting to the solenoid. Because the ball was pushing on the latch, there was a lot of friction. The solenoid needed a larger pulse. This meant more capacitors had to be added.

After a short time of collaborating, Jen had a timer that worked for releasing the ball at random times.

The Auto Release Feeding Frenzy, ARFF, for short has been in use for the last few weeks. Jen has noticed a significant decrease in the number of items ending up in the yard. Jen has had many requests to build more to test on other dogs, but feels she needs more time to evaluate if this solution is going to work long term.

Job well done, way to go Jen and Mike!

June 14th, 2016

June 14th, 2016  johnmaushammer

johnmaushammer